Blog

Enhancing Risk Management using AI

In an era where artificial intelligence (AI) has become a cornerstone of innovation across various industries, its application in enhancing risk management processes is both a promising and evolving frontier. Risk assessments, a critical component of any health and safety program, traditionally rely on manual evaluations to identify, analyse, and mitigate risks. However, the integration of AI into this process signifies a new chapter in efficiency and effectiveness. This blog post aims to explore how AI can revolutionise risk assessments, focusing on its application in building comprehensive risk evaluations and refining risk scoring mechanisms. We will delve into a practical example of a health and safety risk assessment created by AI, including a risk matrix and associated risks, followed by a critique of its advantages and limitations. Finally, we will examine how AI can be used to score risks, considering inherent risks, control measures, and residual risks, providing insights into the potential of AI in transforming traditional risk management approaches.

Harnessing AI for Comprehensive Risk Identification

The first step in using AI for risk assessments involves utilising it to identify potential risks. AI can analyse historical data, incident reports, and even social media to predict and identify risks that might not be evident through traditional methods.Once risks are identified, AI can further assist by providing detailed descriptions of each risk, tailoring the risks with greater specificity based on input from the user regarding their particular circumstances and needs, thereby offering a more customised and relevant risk assessment. You can ask for the risk to be tagged in a way that will make it easier for you to filter the risks on, and also be able to identify an owner of the risk in your organisation. This process not only saves time but also ensures that the assessments are thorough and consider various scenarios that humans might overlook. To customise your risk matrix further to suit your risk appetite for maximum benefit, learn how to optimise your Risk Matrix.

AI Created Health and Safety Risk Assessment

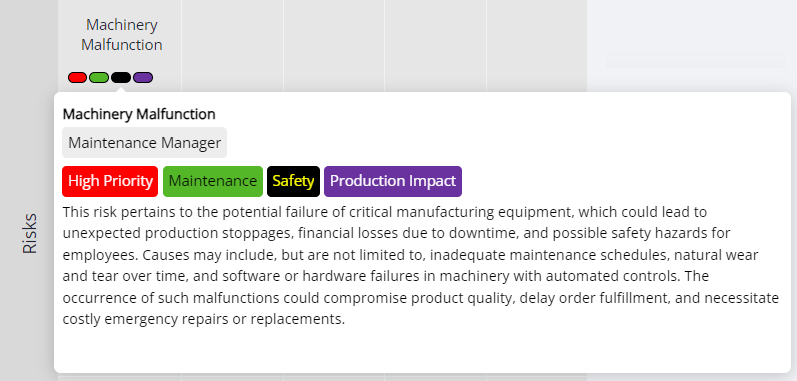

Let's consider a hypothetical workplace scenario in a manufacturing plant to illustrate how AI can identify regulatory/appropriate risks. It identifies "Machinery Malfunction" as a significant risk. This risk encompasses scenarios where critical machinery could fail, potentially halting production and risking worker safety. The detailed description provided by the AI includes possible causes such as inadequate maintenance, wear and tear, or software glitches in automated systems. The AI suggests the "Maintenance Manager" as the owner of this risk, given their responsibility for machinery upkeep and safety compliance. Necessary tags attached to this risk could include "High Priority," "Safety," and "Production Impact," enabling efficient risk categorisation and prioritisation in the plant's risk management system. This example demonstrates AI's capability to pinpoint specific risks, assign responsibility, and facilitate targeted mitigation strategies, ensuring a proactive approach to managing potential hazards in the workplace.

Then we can input historical incident data, maintenance records, and employee feedback to create a risk matrix based on our risk tolerance. It categorises risks into 'High', 'Medium', and 'Low', based on the likelihood of occurrence and the potential impact on health and safety.

HIGH RISK.

Machinery malfunction leading to potential injury. AI identifies this based on recurring maintenance issues and previous incident reports.

MEDIUM RISK.

Slip and fall accidents due to occasional spills. Identified through employee feedback and incident logs.

LOW RISK.

Minor cuts or abrasions from handling materials. Based on low-frequency reports and minor medical treatment records.

Scoring Risks with AI

Let's take the "Machinery Malfunction" risk for further analysis. We can then input information associated to the particular risk, such as: regular maintenance schedules, employee training programs, and any past incident logs related to machinery malfunctions. This detailed input enables the AI to consider both the effectiveness of existing controls and the historical frequency and severity of incidents. By applying these inputs to our custom risk matrix identified earlier, the AI assesses the inherent risks, evaluates the strength of the implemented controls, and then calculates a residual risk score. The following is what was identified in our specific example.Inherent Risk: High. Considering the machinery's critical role and the severe impact of potential malfunctions, the inherent risk is significant.

Control: Good - Implementation of regular maintenance checks and employee training on emergency shutdown procedures.

Residual Risk: Medium. With controls in place, the likelihood of injury is reduced, but not eliminated, due to the possibility of unforeseen equipment failures.

Remediation Planning

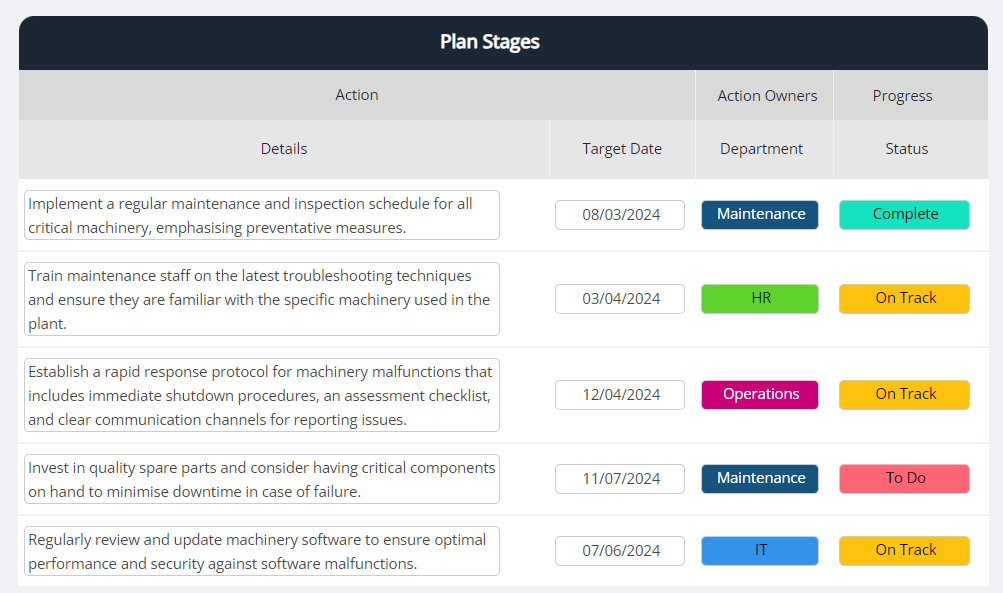

Upon determining the residual risk score, the AI can assist in formulating a tailored remediation plan. This plan prioritises actions based on the risk score and suggests additional controls or modifications to existing practices to further mitigate the risk. A remediation plan identified for our example goes as follows:- Implement a regular maintenance and inspection schedule for all critical machinery, emphasising preventative measures.

- Train maintenance staff on the latest troubleshooting techniques and ensure they are familiar with the specific machinery used in the plant.

- Establish a rapid response protocol for machinery malfunctions that includes immediate shutdown procedures, an assessment checklist, and clear communication channels for reporting issues.

- Invest in quality spare parts and consider having critical components on hand to minimise downtime in case of failure.

- Regularly review and update machinery software to ensure optimal performance and security against software malfunctions.

The Maintenance Manager, in collaboration with the safety and operations teams, will conduct monthly reviews of machinery performance metrics and maintenance records to identify any trends indicating an increased risk of malfunction. These reviews will also evaluate the effectiveness of the current mitigation strategies and, if necessary, adjust them to better address the identified risks.

LET'S COMPARE

Exploring the use of AI for risk assessments reveals a landscape of both promising advantages and notable challenges.

Pros

- Analysis of large datasets quickly, identifying risks faster than manual methods.

- With access to diverse data sources, AI can identify a broader range of risks.

- Forecast potential risks based on trends, enhancing proactive risk management.

- Offering unbiased risk assessments, eliminating human errors or biases that might affect the analysis.

Cons

- The quality of AI-generated assessments heavily depends on the quality and quantity of the data fed into it.

- Potentially miss nuances that experienced professionals can spot, as it relies on data rather than human judgment.

- Not accounting for newly emerged regulatory risks if their training data isn't continuously updated, leading to potential compliance gaps.

The integration of AI into risk assessments offers a promising avenue for enhancing the identification, analysis, and mitigation of risks in various settings. While the efficiency and comprehensive nature of AI-driven processes are notable advantages, challenges related to data dependency, complexity, and the need for human oversight remain. As AI technology continues to evolve, its application in risk management is expected to become more refined, offering sophisticated tools for safeguarding health and safety in the workplace. The balance between leveraging AI's capabilities and addressing its limitations will be key to maximising its benefits in risk assessments.

AI models operate within the confines of their training data, which includes historical information up to their last update. Consequently, they might not recognise or adequately assess new regulatory risks that emerge after their training period. This limitation means that unless the AI's knowledge base is regularly updated to reflect the latest regulatory changes and compliance standards, there could be significant gaps in the risk assessments it generates. Such oversight could lead to non-compliance issues, as organisations might remain unaware of new legal requirements or fail to implement necessary controls and measures to mitigate these emerging risks. For a deeper dive into how to navigate the evolving landscape of AI regulation and effectively manage emerging risks, consider reading our detailed piece on AI Regulation and Emerging Risks. This underscores the importance of complementing AI-driven assessments with ongoing human oversight to ensure that the organisation's risk management practices remain aligned with the current regulatory landscape.